As one of the most widely used valve types in the world, ball valves are extensively applied in industrial manufacturing. They are known for their compact, robust design and reliable, quick on/off operation. A ball valve utilizes a bored ball that rotates 90° to open or close the valve. In the open position, the ball aligns with the inlet and outlet to allow media passage; in the closed position, the ball seals tightly against the seat to seal off flow. Since their introduction in the 1950s, ball valves have been a dependable solution for flow control in industrial manufacturing, offering low maintenance costs and contributing to their widespread adoption.

Ball valves are generally classified by ball structure into two main types: floating ball valves and trunnion ball valves. FITOK manufactures multiple series of both types. What are the distinguishing features of each? This article introduces both valve types and compares their characteristics.

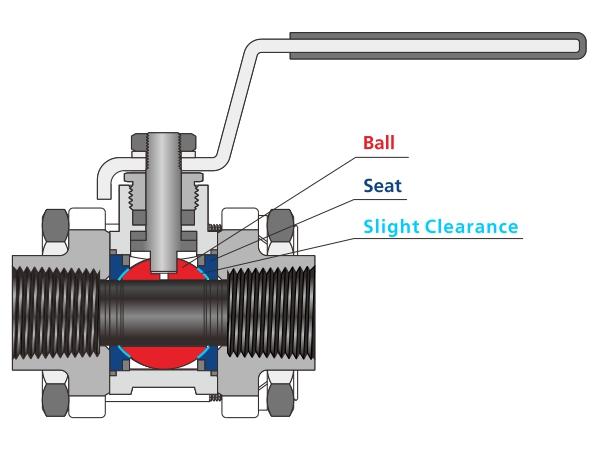

Floating Ball Valves

The floating ball valve is the most traditional and widely used type. In this design, the ball is not rigidly fixed within the valve body but is allowed to float, with a slight clearance that allows limited movement. When the valve is closed, upstream pressure pushes the ball to move, pressing it tightly against the downstream seat to create a tight seal. Floating ball valves have a simple structure, resulting in lower manufacturing costs and easier maintenance. However, they also present some limitations: At high pressures, operating torque increases significantly, making the ball more difficult to rotate. In many cases, manufacturers provide only a single seat, so many floating ball valves support only unidirectional flow.

Trunnion ball valve.

FITOK addresses these challenges with tailored solutions. For certain floating ball valve series, FITOK offers multiple handle options, allowing users to select the most suitable type to reduce operating effort. Additionally, all FITOK 2-way floating ball valves are designed with a symmetrical structure, providing full bidirectional flow capability.

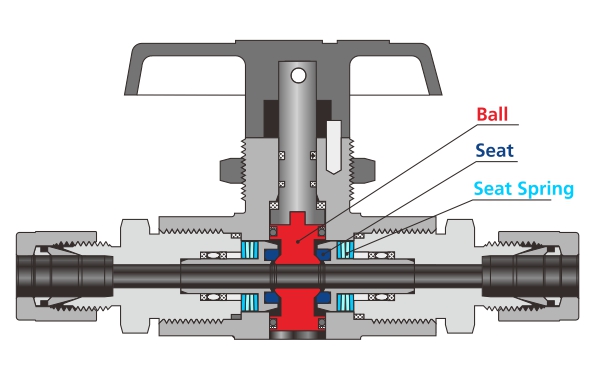

Trunnion Ball Valves

Unlike floating ball valves, in a trunnion ball valve, the ball is anchored by the upper stem, lower stem, and bearings, eliminating any movement within the valve body. Instead, the valve is designed with floating seats. When the valve closes, the spring preload from the loading mechanisms and the media pressure act together on the seats, pressing them tightly against the ball to achieve sealing. With the fixed ball, this structure reduces rotational friction and operating torque. However, trunnion ball valves have a more complex structure, are more expensive to manufacture, and are more challenging to maintain compared with floating ball valves.

Trunnion ball valve.

FITOK introduces unique disc spring-loaded seats in certain trunnion ball valve series. These seats apply sufficient pressure against the ball for reliable sealing and compensate for seat wear, thereby extending service life. Thanks to their enhanced performance, trunnion ball valves deliver longer operating life in harsh environments. Although their initial cost is higher, the total cost of ownership can be lower over the valve’s lifecycle. Furthermore, FITOK offers trunnion ball valve series with a top-loaded design, featuring a removable bonnet that allows direct access to internal components without removing the valve from the pipeline. This feature enables online maintenance and adjustment, significantly reducing maintenance time and simplifying service operations.

Comparison between Floating Ball Valves and Trunnion Ball Valves

Floating Ball Valves | Trunnion Ball Valves | |

Sealing Principle | Media pressure pushes the ball against the outlet seat to achieve sealing. | Spring preload and media pressure jointly act on the floating seats, pressing them against the ball for sealing. |

Ball Status | The ball is driven by the stem and can move slightly toward the outlet. | The ball is fixed by upper and lower stems and bearings; it only rotates without axial movement. |

Structure | Relatively simple structure. | More complex structure with floating seats and bearing support. |

Applicable Pressure | Low to medium pressure. | High pressure. |

Operating Torque | Higher, especially under high pressure or in larger sizes, as the ball directly presses against the seat, increasing friction. | Lower, as the fixed ball reduces rotational friction, resulting in easier operation. |

Manufacturing Cost | Lower. | Higher |

FITOK Series | BG / BH / BP, etc. | BF / BO / 10B, etc. |

Our featured manufacturer FITOK has extensive expertise in the design and manufacture of ball valves. Many of the features highlighted in this article—such as multiple handle options and top-loaded designs—are not limited to a single valve type. For specific application requirements, FITOK can provide customized solutions.

For more information, please refer to FITOK's ball valves catalogs. You can also contact us to get advices on your adequate ball valve selection!

More blog articles: